- 1.Automatic Rotor Controller

- 2.Automatic Slip Regulators

Slip ring motors require a high starting torque, and require additional starters. This is achieved by connecting additional starting resistances while starting the rotor circuit. As a result, we require starters that operate on full motor voltage and high starting torque. External resistance is added through slip ring of the motor which restrict the starting current & boost torque to drive various applications.

We have two models in Slip ring starters :

Both models are used for different applications, but work on the principle of varying the rotor frequency with the magnetically amplified resistance.

Automatic Slip Regulators are preferred for Sugar Industry applications such as Fibrizor, Crusher, Chopper, Cutters and Levellers.

Automatic Rotor Controllers on the other hand are preferred for applications like Pumps (Centrifugal, Vertical turbine, Mixed flow, Oil hydraulic), Compressors (Centrifugal, Reciprocating, Process Compressor, Refrigeration, Screw, Air-conditioning) and heavy equipment (Ball Mill, Crusher, Fans) etc.

Automatic Rotor Controller

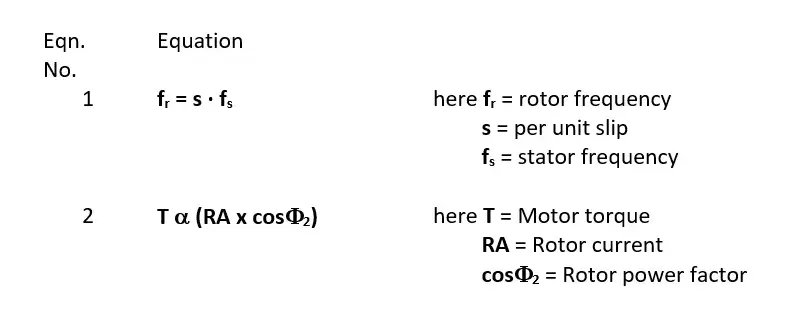

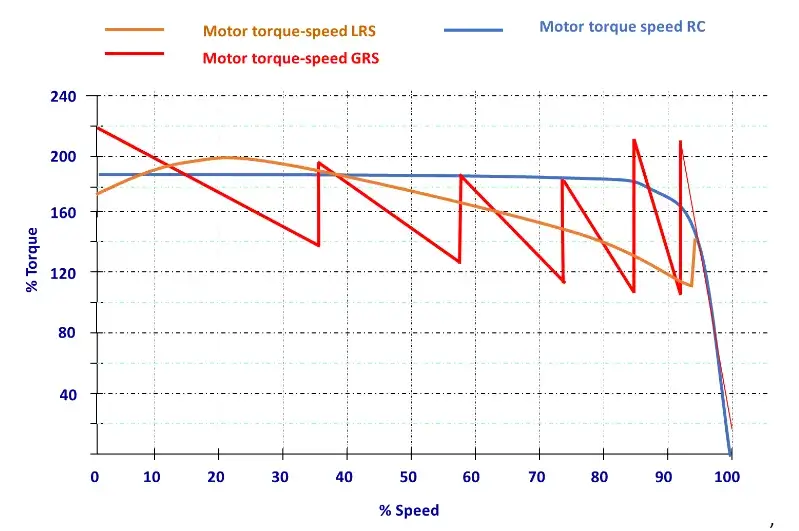

Automatic rotor controller starters work on the principle of a magnetically amplified resistance which is directly proportional to the rotor frequency. They are designed with a lossy core and help lower the starting current by automatically reducing resistance proportional to motor speed. As per the Slip ring motor theory the rotor frequency of the motor is proportional to the Slip, and Torque is proportional to the active component of the rotor current. These are represented as

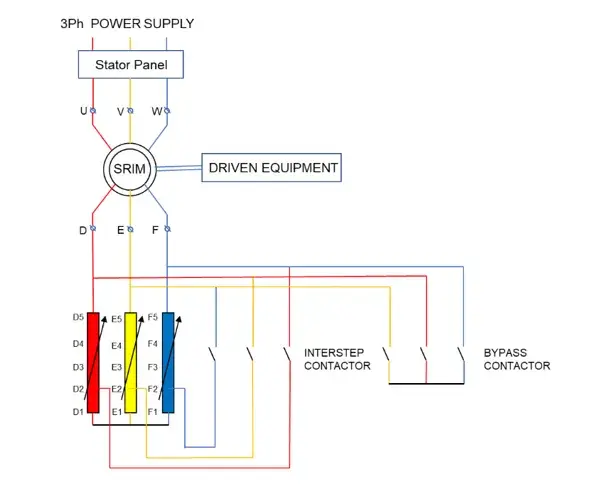

FCMA soft starters reduce starting current, accelerates motor to full speed and then is bypassed when

the motor reaches full speed Thus ensuring that the motor continues to run regularly on full voltage.

The circuit diagram below illustrates the working of the soft starter.