- 1.FCMA plus Reactor based Soft Starter

- 2.Electronics Thyristor based SCR soft starter

When one thinks of starting an electric motor in an industrial application, the words “Direct on Line

(DOL)”, “Star Delta”, “Auto Transformer” and “ Soft Starter” usually come to mind. A Star-Delta starter,

“Auto Transformer”, and a “Soft Starter”, all help in lowering the starting current at which a motor

starts. Lowering the starting current ensures the grid is protected from excess load, and the motor is less

susceptible to long term damage. However, when we deal with large capacity motors running at

medium and high voltages, the soft starter is the most preferred mode of starting. This can be primarily

attributed to the fact that not all starting methods allow for a significant reduction in the starting

current to the scale offered by the soft starter. A Soft Starter is an advanced “Motor Starter”, a device

that allows for smooth motor starting, by reducing the starting current of a motor which works by

reducing the voltage drop across the motor. A “soft start” ensures a smoother, safer and gradual start-

up, by extending the lifespan of the motor and also lesser voltage drops on the system. By lowering the

starting current, it ensures that the grid is protected from excess load, voltage drops and ensures that

other consumers are not affected with the starting of a large motor.

The soft starter technology consists of two types:

Both starters can be used in different applications for different voltage ranges. Electronic soft starters are typically more popular for lower voltage i.e. up to 600 Volts and low capacity motors up to 200 KW applications, while FCMA soft starters, given their reliability and ruggedness, find greater use in the Medium Voltage Range, and higher capacity beyond 200 KW. In medium voltage range, reliability and continuation of the equipment availability i.e. MTBF is very critical. Replacement and maintenance is significantly more difficult. This makes the FCMA soft starter the best alternative in MV applications.

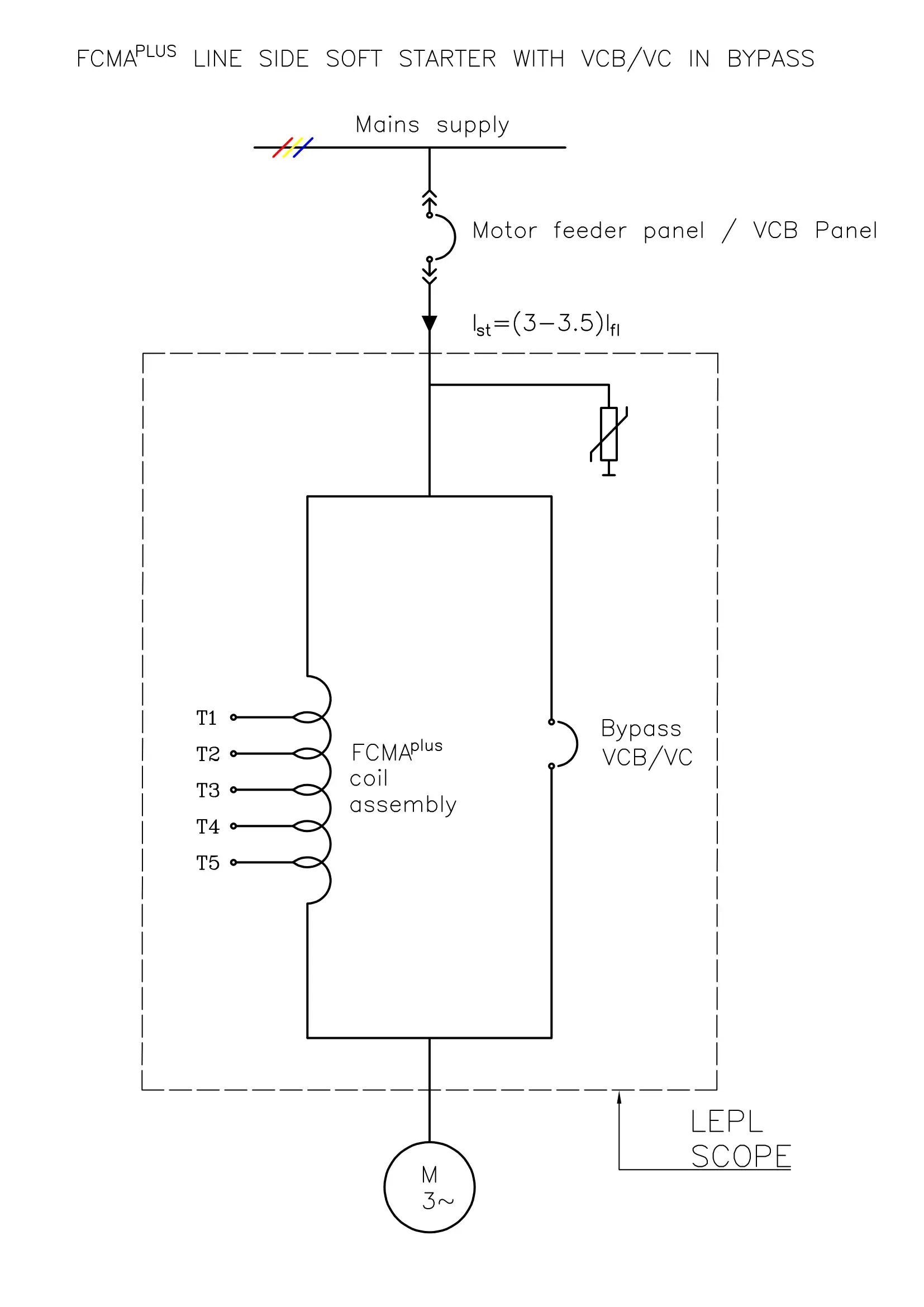

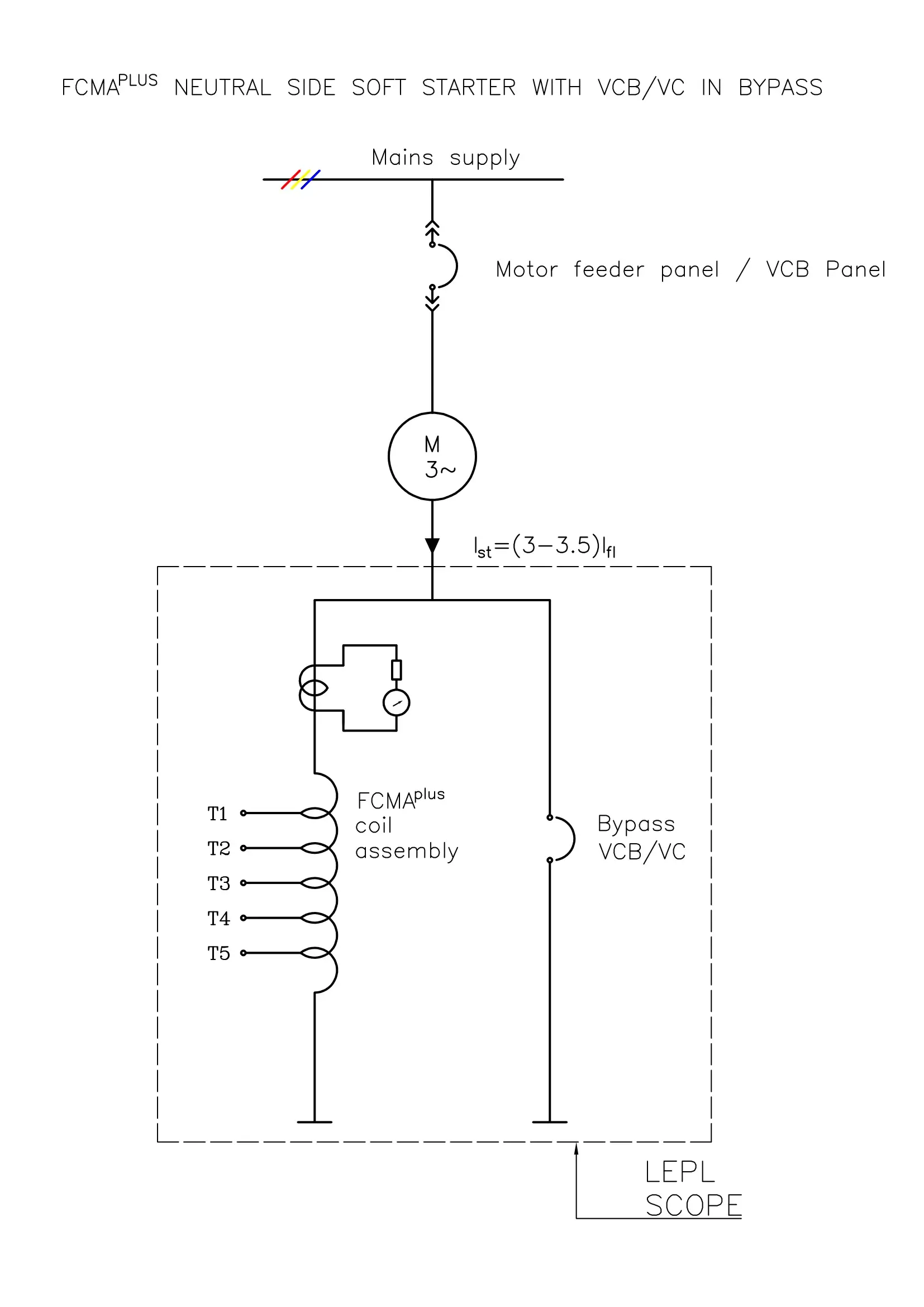

FCMA plus Reactor based Soft Starter

The FCMA soft starter is based on the principle of reactive impedance where the motor voltage

increases gradually as motor accelerates to full speed. It does not generate any harmonics and therefore

gives minimum starting current at site. The main advantage of the FCMA plus is its ruggedness and simple

design that allows for ease of operation and maintenance. It also offers reliable quality at commercially

attractive prices with a long life. The FCMA plus soft starter also allows for greater flexibility, customization

and can help lower the starting current to as low as 1.2 times the full load current. Each type of soft

starter is installed in a panel and comes with various switchgear components along with different

protection equipment such as a CPR, isolator, fuse, VC or VCB etc.

FCMA soft starters reduce starting current, accelerates motor to full speed and then is bypassed when

the motor reaches full speed Thus ensuring that the motor continues to run regularly on full voltage.

The circuit diagram below illustrates the working of the soft starter.